Providing a high-quality, technology-enabled global survey & inspection service built on a foundation of quality and governance that helps our clients achieve safety, commercial, and ESG excellence.

At Inchcape, we understand the critical importance of minimising risk in the maritime industry. Our comprehensive survey and inspection services are meticulously designed to protect your assets, enhance operational efficiency, and ensure regulatory compliance. We offer a holistic approach that covers every aspect of your vessel’s operations, allowing you to focus on what you do best – growing your business.

By choosing Inchcape as your survey and inspection partner, you gain access to a global network of highly experienced surveyors, comprised of ex-seafarers, Master Mariners, Chief Engineers, and Naval Architects. This dedicated team operates under a robust governance framework, ensuring that risks are not only detected but mitigated with utmost precision.

What sets us apart is our unrivalled combination of global and local expertise. Seamlessly connecting with our in-house survey teams and an extensive network of partners worldwide, we leverage valuable local knowledge and professional operational excellence. Our single global contact point, integrated with World of Ports, guarantees a seamless experience throughout your entire voyage.

Product Specifications

-

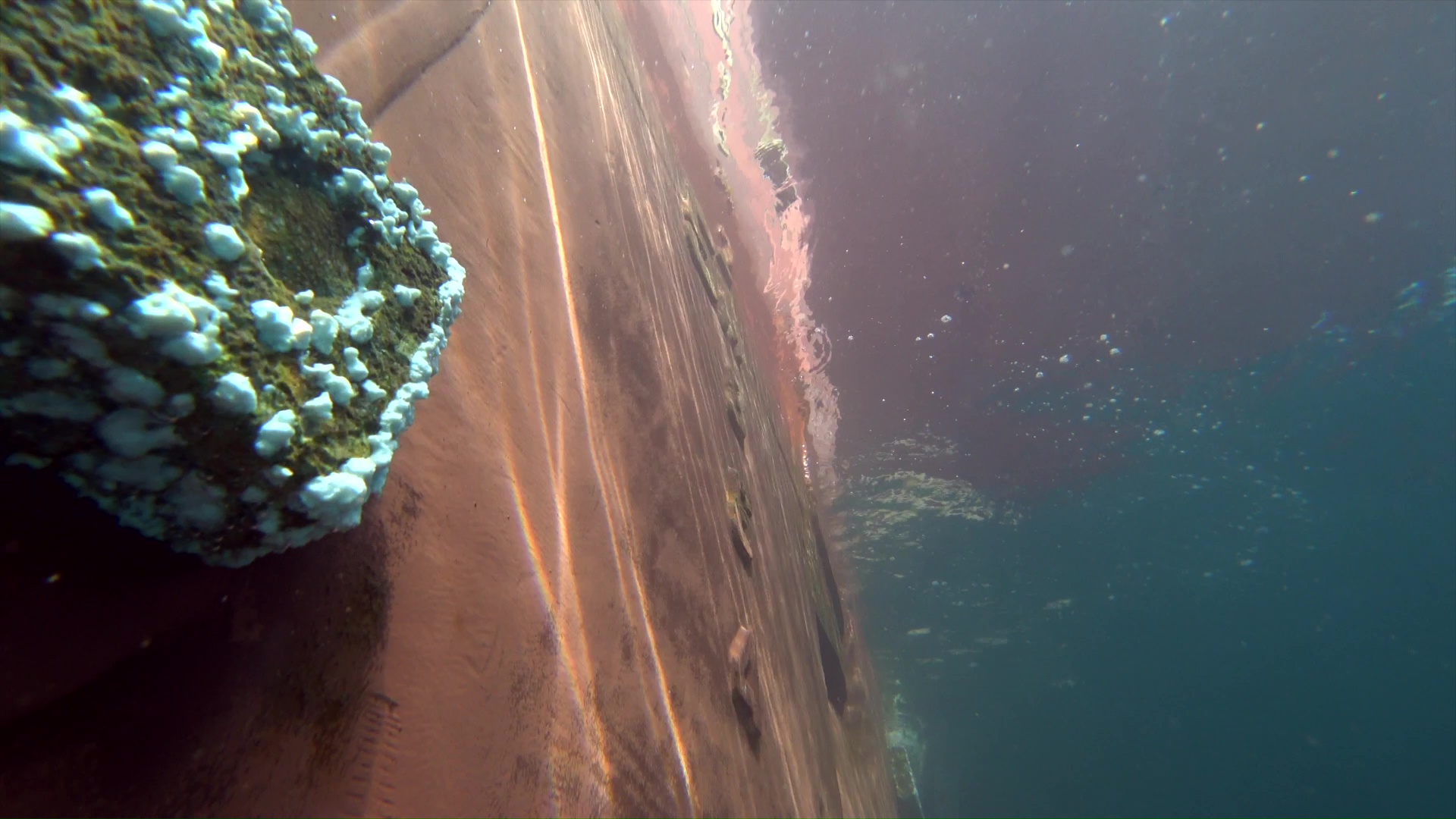

Underwater Inspection

Underwater inspections are a visual examination of the underwater elements of the hull, performed by Inchcape’s using ROVs or by divers, via our partners, to assess the condition of the underwater elements of the hull and components for the integrity of protective coatings, biofouling, or damage. Inchcape partners with leading paint manufacturers and hull cleaners to ensure minimal delay in resolving issues.

Hull & Machinery Survey

A comprehensive inspection and assessment of a vessel’s hull, machinery, and related equipment to ensure compliance with charter, commercial, or safety standards helping shipowners, operators, and insurers make informed decisions regarding vessel maintenance, repairs, insurance coverage, and overall risk management.

-

Breakbulk Port Captain

A Breakbulk Port Captain survey is performed to assess the quality, condition and quantity of break bulk cargoes as well as their loading, stowage, and securing. Breakbulk cargoes are non-containerized goods that are typically loaded individually or in smaller quantities onto a vessel.

Bulk Buyers Inspection

A Bulk Buyers inspection is a pre-shipment visual inspection of bulk cargoes on behalf of buyer/seller or insurers, to verify that the goods conform to contractual specification and to international export regulations and requirements.

Draft Survey

A draft survey is performed to determine the weight/volume of cargo loaded or discharged from a vessel by measuring the change in its draft (the vertical distance between the waterline and the bottom of the vessel) before and after loading or unloading.

Hold Survey – Cleanliness

A hold cleanliness survey is an inspection conducted to assess the cleanliness and condition of cargo holds on a vessel to ensure the vessel is suitable to take its new cargo and that contamination will not occur.

Hold Survey – Damage

A hold damage survey is an inspection conducted to assess and document any damage or defects in the cargo holds of a vessel. It is typically performed after cargo operations, such as loading or discharging, to identify and record any structural damage, deterioration, or other issues that may have occurred during the process.

Hatch Cover Integrity

A hatch cover integrity survey is an inspection conducted to assess the condition and effectiveness of the hatch covers on a vessel. Hatch covers are the closures that seal the cargo holds, ensuring the protection of cargo from external elements such as water, moisture, and weather conditions. This survey is typically performed to verify that the hatch covers are in good working order and capable of providing a watertight seal.

Loadmaster / Port Superintendent

The Loadmaster/Port Superintendent monitors the loading and/or discharge of bulk cargo on a vessel. A Loadmaster/Port Superintendent is responsible for overseeing the safe and efficient loading, securing, and unloading of bulk cargoes, such as grains, ores, coal, fertilisers, or other dry or liquid bulk materials that are loaded directly into the cargo holds without individual packaging.

Petro / Chemical Cargo Operations

Petro/Chemical Cargo Operations service is conducted to monitor the loading or discharge of liquid cargoes to/from a vessel.

Pipe and Steel Survey

A pipe and steel survey is conducted to assess the condition, quantity, and handling of the cargo during transportation or storage to ensure that they are handled properly, meet quality standards, and are in suitable condition for their intended use.

Stockpile Survey

A stockpile survey is conducted to determine the quantity, quality, and condition of materials or goods stored in a stockpile. It involves measuring and documenting the volume or weight of the stockpile, inspecting its contents, and providing relevant information for inventory management or

other purposes. -

Bunker Quantity Survey (BQS)

A Bunker Quantity Survey (BQS) is conducted to determine the quantity and quality of bunker fuel received by a vessel. It involves precise measurements and calculations to accurately determine the amount of fuel provided.

Bunker Sampling & Analysis

Bunker Sampling & Analysis involves the collection of fuel samples from bunkering operations and conducting laboratory tests to assess the quality and compliance of the fuel with specified standards or regulations. This process is crucial for ensuring that the bunker fuel meets the required

specifications and does not pose any risks to the vessel’s operation or the environment.Forensic Bunker Survey

Forensic Bunker Surveys are a specialised inspection conducted to determine the cause, extent, and consequences of a bunker-related incident. It involves a detailed examination and analysis of the bunker fuel storage and handling systems, as well as associated equipment and infrastructure.

-

Cargo Handling & Stowage

The Cargo Handling & Stowage surveys are conducted to plan and monitor the handling and stowage of cargo on a vessel to ensure that proper procedures are followed, cargo is handled safely, and it is stowed securely to prevent damage during transportation.

Cargo Lashing Supervision

Cargo Lashing Supervision is performed to oversee and verify the proper securing of cargo on a vessel to ensure its stability and safety during transportation. It involves the supervision of cargo lashing operations and the issuance of a certificate or document confirming that the cargo has been adequately secured.

Cargo Logistics

A Cargo Logistics Survey is conducted to evaluate the logistics aspects of cargo transportation and distribution. It involves analysing various factors related to the movement of goods, including transportation modes, routes, storage facilities, handling procedures, and overall supply chain efficiency. The purpose of a cargo logistics survey is to identify potential bottlenecks, inefficiencies, or areas for improvement in the cargo logistics process.

-

Sale & Purchase (S&P)

A Sale and Purchase (S&P) inspection is an assessment conducted on a vessel or ship during the process of buying or selling it. The purpose of this survey is to evaluate the condition, seaworthiness, and overall value of the vessel. It provides crucial information to the buyer and seller, helping them make informed decisions regarding the sale or purchase.

Ship Vetting

A Ship Vetting inspection is an assessment conducted to evaluate the suitability and safety of a ship for a specific task or operation and to ensure the vessel meets certain standards, complies with regulations, and poses minimal risk in terms of safety, environmental impact, and operational performance.

On/Off-Hire Condition Survey

The On/off-hire Condition Survey is performed to assess the condition of a vessel at the time of its delivery (on-hire) or redelivery (off-hire) to/from a charterer or owner. The survey will document the condition of the vessel or equipment and determine any changes or damages that may have occurred during the charter period.

-

Crane Inspection

A Crane Inspection is conducted to ensure the safe and reliable operation of the ship’s cranes, which are essential for cargo handling, lifting operations, and other tasks on board. Specific requirements for ship crane inspections may vary depending on factors such as the type of crane (e.g., gantry crane, deck crane), its capacity, the vessel’s flag state regulations, classification society rules, and any additional requirements set by charterers or port authorities.

Wire Inspection

A Wire Rope inspection is a thorough assessment conducted on the wire ropes used on a ship or vessel. Wire ropes are critical components in various maritime applications, including lifting operations, mooring, towing, and anchoring. The purpose of this inspection is to ensure the integrity, strength, and safety of the wire ropes.

-

Lloyds Agency

Lloyd’s Agency ship inspections are performed on behalf of shipowners, charterers, insurers, and Protection and Indemnity (P&I) clubs. Inchcape’s Lloyd’s Agency surveyors conduct inspections objectively and provide accurate and reliable information to assist clients in making informed decisions or resolving issues related to the ship for issues such as claims adjustments, or cargo disputes.

Marine Warranty Survey (MWS)

A Marine Warranty Survey (MWS) is conducted to assess and provide independent verification of the safety and feasibility of marine operations. These surveys are typically required by insurance companies, project owners, or other stakeholders to mitigate risks associated with high-value or complex marine operations.

Protection & Indemnity (P&I) Survey

Protection and Indemnity (P&I) surveys are an objective inspection conducted by a surveyor on behalf of a P&I club. P&I clubs are mutual insurance associations that provide liability coverage to shipowners and operators for various risks associated with the operation of ships.

Proof & Protection of Asset

The Proof & Protection of Asset survey is to establish an accurate representation of the commodity’s quality, quantity, and condition. This information is often required for trade, insurance, legal, or regulatory purposes.

-

Citadel Inspections

A ship citadel inspection involves a detailed examination of the citadel, which is a heavily fortified and protected area of a ship designed to provide a secure space for personnel in the event of an attack or emergency. Citadel inspections are particularly relevant for ships operating in high-risk areas where there is a potential for piracy or armed attacks.

Ship Security Assessment (SSA)

Comprehensive evaluation of the security measures and protocols implemented on a vessel to safeguard it from security threats and risks. This assessment is a critical component of the International Ship and Port Facility Security (ISPS) Code, which is an international maritime security standard established by the International Maritime Organisation (IMO).

Anti-Piracy Ship Security Assessment (APSSA)

A specialised evaluation focused on identifying and mitigating security risks related to piracy threats for a specific vessel. The goal of an anti-piracy ship security assessment is to enhance the vessel’s security measures and protocols to minimise the risk of piracy incidents.

Ship Security Plan (SSP) Review

A systematic examination and assessment of the effectiveness, adequacy, and compliance of a vessel’s Ship Security Plan. The Ship Security Plan is a comprehensive document developed to ensure the security of ships and port facilities in accordance with the International Ship and Port Facility Security (ISPS) Code, established by the International Maritime Organisation (IMO). The Ship Security Plan review is typically conducted periodically, and it may be triggered by changes in the ship’s operation, security incidents, or regulatory updates.

Port Security Assessment (PSA) per ISPS

A thorough examination of the security measures and procedures implemented at a port facility to ensure compliance with the International Ship and Port Facility Security (ISPS) Code. The ISPS Code is an international maritime security standard established by the International Maritime Organisation (IMO) to enhance the security of ships and port facilities.

Survey & Inspection Brochure

Our Services

Port Agency

Services designed specifically around the needs of our customers, including full port agency, crew logistics, husbandry, dry docking, and more

Global Managed Solutions

High level, standard services worldwide, with the most comprehensive range of managed solutions designed around you.

Digital Solutions

Control, visibility and transparency of your entire port call operation through an intuitive digital platform. Plan and track your cargo and vessel.

Marine Services

Specialist support when you need it most, including machinery, survey and inspection, project management and handling of spare parts and consumables.